Güray Taşlamacarries out its operations with an experienced team and machines integrated with the latest technology, always positioning itself as a reliable partner for its valued customers. In plastic injection molding, certain product characteristics are determined by the mold. In other words, the shape, dimensions, quality, and tolerances of the product are primarily defined by the mold, which ensures that the plastic coming from the machine’s melting unit is formed into the final product. So, what are Güray TaşlamaPlastic Injection Molds? Why are plastic injection molds used?

To answer the question "What is a plastic injection mold?" we first need to explain that plastic injection refers to a manufacturing method in which plastic raw material is melted at high temperatures and injected into a mold. This production method is widely used in industrial fields and is crucial for manufacturing. Many products we use today are produced through plastic injection molding.

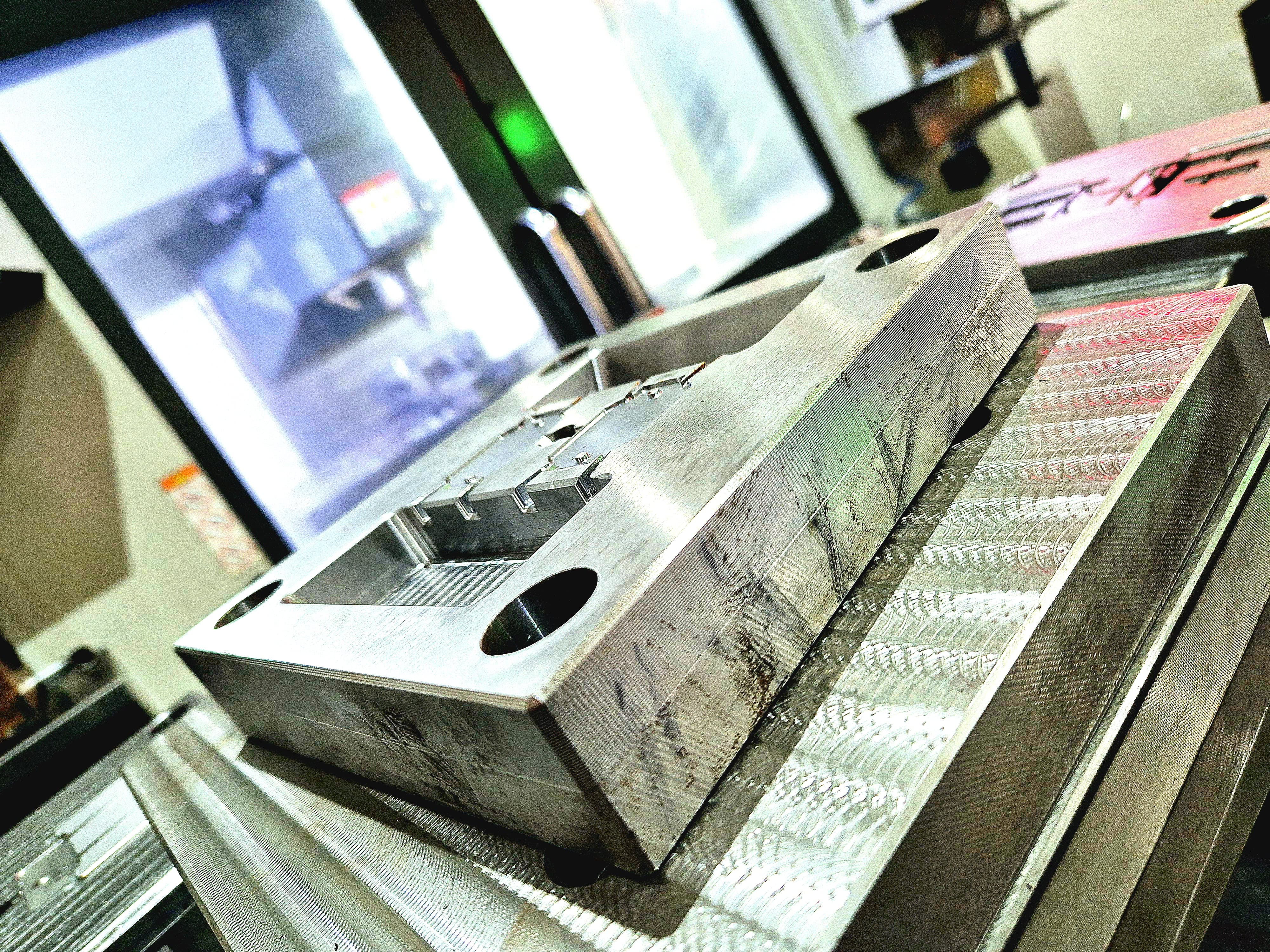

The working principle of plastic injection is quite simple. The melted plastic raw material is injected into a mold and shaped. Afterward, it is cooled and removed from the mold. This manufacturing method is used for many plastic parts. Today, plastic injection molds are integrated with computer systems, using the latest technologies to produce high-quality results.

Güray Taşlama Plastic Injection Molds

With Güray TaşlamaPlastic Injection Molds, once the plastic material is injected into the mold and fully fills it, the material takes its shape. It is then solidified through cooling and removed from the mold for production. The process is completed by filling the mold with molten raw material, stabilizing it with holding pressure, and allowing the material to harden and cool within the mold.

Güray Taşlamaoperates with an experienced team and machines integrated with the latest technology, always standing by its valued customers. With plastic injection molds, the shape, dimensions, quality, and tolerances of the product are primarily determined by the mold, which ensures that the plastic, coming from the machine’s melting unit, reaches its final form and is used in your production processes. For more information and to view our molds, contact us today and take advantage of our competitive prices.